12 December 2018

Latest Radan software release does more with fewer clicks

A company-wide investment in development, combined with data from software analytics, means the latest updates are based largely on customer usage and preferences. Product Manager Olaf Korner says analytics have been able to identify common themes – the sequences people click most, and why. “It shows how customers achieve certain results, and we’ve used those measurements to incorporate sequences that are used many times every day, into just one click.”

A company-wide investment in development, combined with data from software analytics, means the latest updates are based largely on customer usage and preferences. Product Manager Olaf Korner says analytics have been able to identify common themes – the sequences people click most, and why. “It shows how customers achieve certain results, and we’ve used those measurements to incorporate sequences that are used many times every day, into just one click.”

A significant update in Radan 2019 R1 makes the popular Radquote function easily accessible to different categories of employees. “Radquote users are generally not the staff who program machine tools with Radan. So we’ve made Radquote completely standalone and easy to use by anyone – automatically using machine technology for the quote, with Radquote calculating the accurate cycle time and the best material usage.” This achieves an accurate quote every time, providing consistency and transparency, irrespective of who is producing the quote.

Radquote not only competitively calculates costing on sheet metal, but all aspects of quoting are now included – such as cutting, bending, welding, painting and assembly.

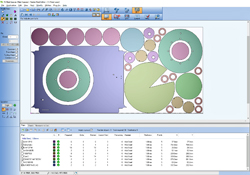

Radan CAD/CAM is a key area where click habits have been reviewed and advanced for simpler use – saving time and refining business processes. “Part preparation is a time-consuming task and some operations have been reduced from two clicks to one, to apply settings. The Grab Part In Nest mode function, to change a part in nesting mode, has also been simplified saving average users an estimated minimum of 50 clicks per day.”

Three important updates feature in Radbend, including: improved automatic fingerstop positioning for sharp-angled parts; pre-selection of the bend process depending on the tool selection; and filter tool profiles.

Radm-ax developments include automatic heat avoidance, hazard avoidance and common line cutting. A new cutting sequence for heat avoidance has been added to prevent heat build-up in the component. Improvements to hazard avoidance, calculating a better and safer path around hazards, and an increase in the ability to cut more difficult angles, such as 30-degree angles, with common line cutting, will also benefit production times.

- Contact Information

- Name: Marc Freebrey

- Email: marc.freebrey@verosoftware.com

- Website: www.verosoftware.com